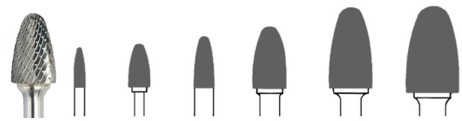

SF-15 Tree Radius Carbide Burr Cutting Tool are used to remove unwanted edges from metals which is called deburring. There are many different sized carbide burr cutting tools that are designed to shape, smooth and clean various types of materials. Carbide burrs and rotary files are used in various applications for deburring, cylinder head porting, mold making, tool and die, metalworking, tool grinding, foundry, aerospace, automotive, dental laboratory, wood carving, farriers, metal smithing, sculpting, welding, chamfering, jewelry manufacturing, die casting, and metal casting.

Intake and Exhaust Cylinder Head Porting Tool

Porting is another method in which application of the carbide burr is necessary. Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the gas flow. Porting the heads provides the finely detailed attention required to bring the engine to the highest level of efficiency. Theoretically, polishing with abrasives affects the fuel flow and ultimately the porting process is responsible for the high power output of modern engines.

Which Carbide Burr Cut Should You Choose?

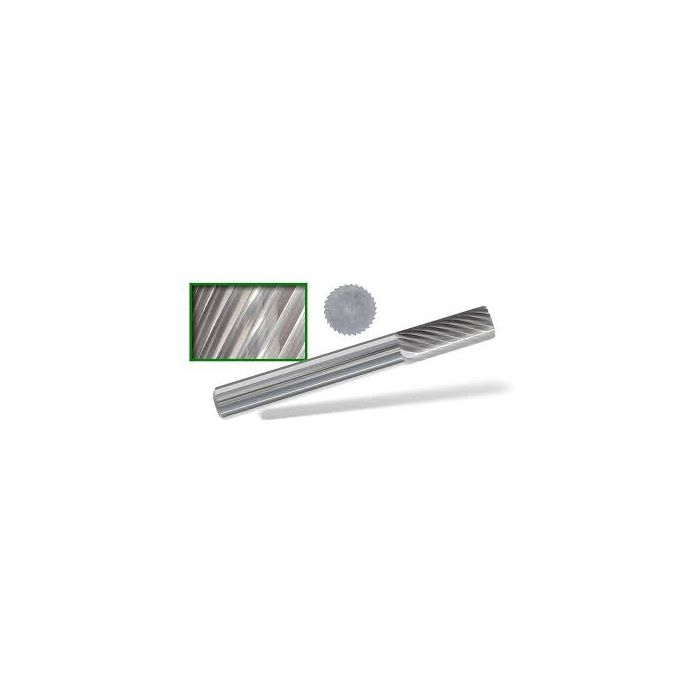

Standard cut carbide burr cutting tool is designed for ferrous materials such as cast iron, steel, brass and copper alloys. Provides an excellent surface finish and removes the unwanted edges very quickly. Right hand spiral flute.

Double cut carbide burrs are designed for deburring heated metals and tough alloys. Right and left hand flutes are combined to produce super smooth finishes. Slight left hand cutting action gives perfect control of both the burr and grinder.

Aluminum cut is used for non-ferrous and non-metallic materials. Works great for fast deburring and minimum chip loading.

For details about what is sf15 Carbide Burrs you can check this resource